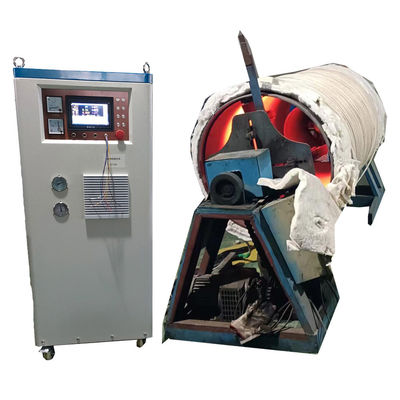

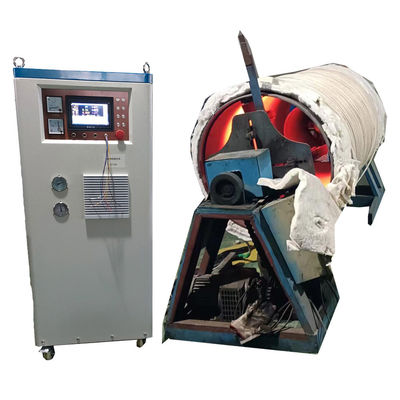

DSP-160KW Air Cooled Induction Heating Machine For Heating Shrink And Expansion, Preheat, Heat Treatment

Application:

Preheating before welding, hydrogen elimination after welding, stress relief heat treatment, heat jacket heat removal, diathermy, hot forging, etc

Application Industries: Nuclear power, military, marine, chemical, power construction, vehicles, engineering machinery, pressure vessels, scientific research.

Features:

1. This equipment uses the digital signal processing (DSP) digital real-time high-speed signal processor and DDS (Direct Digital Synthesizer) direct digital frequency synthesizer. Infieneon IGBT type.

2. Using advanced digital control technology and digital phase-locked loop tracking technology and computer control technology, the system structure is safe and reliable, stable performance and simple operation.

3. Imported integrated circuit and power module are used to realize automatic frequency tracking. It has the characteristics of small size, light weight, high efficiency, energy saving, simple installation, high reliability and not easy to damage.

4. The heating speed is fast and the heating efficiency is high. It can control the heating temperature and time conveniently, and it is easy to ensure the heating quality and the running water operation.

5. Visual digital display of voltage, current, frequency, power, heating time, and heating temperature,etc.

6. Can Predictable power, that is the power can be set before heating is turned on, with high accuracy. This function is not available for other similar products in the market.

7. Friendly man-machine interface:

Human-computer interaction can choose a variety of ways, such as LED indicator or digital tube display, touch screen display and control, text screen display, customers can choose at will according to their needs; from the function realization and operation settings, it covers the traditional mechanical button panel, making the operation and maintenance easier, more intuitive and more convenient;

8. Hardware isolation interface:It can be compatible with the existing PLC on the market, and is conducive to the functional transformation of the existing PLC system and the further expansion of the automation system.

9. Remote communication interface:

10. The device is equipped with a striking red emergency stop button, which can be pressed quickly when an emergency occurs.Stop the equipment immediately to achieve protection measures.

11. Reasonable layout of the internal components of the equipment, the main control circuit board is centralized on the weak side to avoid the interference of the strong current to the control circuit and improve the control accuracy.

12. Induction Heating Machine have remote control function and adopt digital circuit control, power regulation can be adjusted from 0% to 100% resolution.

Technical Parameters:

| Type |

DSP-160KW |

| Rated Output Power |

160KW |

| Rated Output Frequency |

3-15KHZ |

| Input Voltage |

380V/415V/440V/480V 50-60hz |

| Max power |

160kw |

| Protection Level |

IP23 |

| Current |

240A |

| Remote |

Yes |

| Induction Heating Flexible Cables |

50M |

| Size |

700*600*1550MM |

| Weight |

200KGS |

| Protection system |

Yes |

| Heating Temperature |

1-680C |

| Heating Temperature system |

2 Channels |

| Cooled Type |

Air Cooled |

Advantage:

1. Easy to operate, can programme

2. High Waterproof.

3. Can bear high temperature, allow the max environment temperature reach to 180C.

4. High safety.

5. Full digital

6. Anti-interference.

Control Function:

Main wire Switch

Main Part Switch

Remote Switch

System safety Protection

Phase protection

Timmer Switch

Over-heating protection

Over-voltage protection

Over-current Protection

Phase Fail Protection

Power can programme

Display function:

Temperature Checking Display

Time setting Display

Working Model Display

Working state display

Failure inquire display

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!