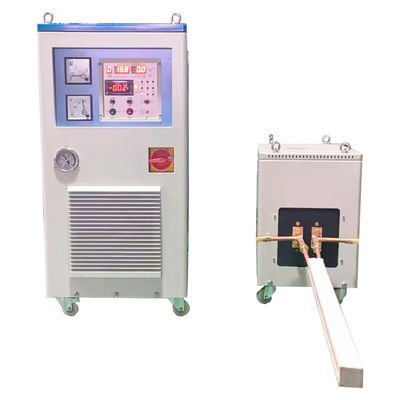

Macchina per tempra a induzione e trattamento termico per vari coltelli

Descrizione del prodotto

Il riscaldamento a induzione è un settore in rapida crescita grazie alla sua efficienza energetica, affidabilità, riproducibilità e velocità. Questa tecnologia offre applicazioni quasi illimitate, tra cui il riscaldamento, l'unione, la brasatura, la tempra e la fusione di parti. Un componente critico è l'induttore, il cui design preciso determina l'accuratezza del riscaldamento. I tecnici esperti della nostra fabbrica, con oltre 25 anni di esperienza, sviluppano induttori con meticolosa precisione dimensionale su misura per la geometria del pezzo.

La precisione è fondamentale nel riscaldamento a induzione, soprattutto quando si applica energia o calore significativi ai pezzi in tempi minimi. L'accuratezza della temperatura è spesso critica per il processo, richiedendo la combinazione perfetta di geometria dell'induttore, frequenza, potenza e caratteristiche del campo magnetico. Questo metodo garantisce una produzione rapida, una distorsione minima del pezzo e un consumo energetico economico.

Caratteristiche principali

Alta efficienza e risparmio energetico - Raggiunge fino al 90% di tasso di conversione energetica riscaldando direttamente i materiali conduttivi tramite induzione elettromagnetica.

Velocità di riscaldamento rapida - Raggiunge temperature fino a 1000°C in pochi secondi per una precisa lavorazione termica.

Controllo preciso della temperatura - Accuratezza di ±1°C con tecnologia PID avanzata per risultati costanti.

Riscaldamento senza contatto - Elimina contaminazione, ossidazione e deformazione del materiale.

Applicazioni versatili - Compatibile con metalli ferrosi/non ferrosi e vari processi industriali.

Design compatto e portatile - Leggero con potenza regolabile (gamma 5kW-50kW).

Funzionalità di sicurezza - Include protezione da sovracorrente, spegnimento automatico e sensori termici.

Ecologico - Nessuna fiamma libera o emissioni dannose, conforme agli standard internazionali.

Soluzioni personalizzabili - Configurazioni su misura per specifici requisiti del settore.

Specifiche tecniche

| Tipo |

HF-80KW |

| Potenza di lavoro |

3*380v/415v/440v/480v 50-60hz |

| Gamma di tensione operativa |

340-430V AC |

| Potenza in uscita |

80KW |

| Corrente in ingresso |

120A |

| Frequenza fluttuante |

30-80khz |

| Portata acqua di raffreddamento |

0.1-0.3Mpa 30L/Min |

| Punto di protezione della temperatura dell'acqua |

40°C |

| Ciclo di lavoro |

100% (temperatura ambiente 40°C) |

| Peso |

Parti principali: 98Kg, Trasformatore: 90kg |

| Dimensioni |

Parti principali: 690*400*650MM, Trasformatore: 530*300*475MM |

Applicazioni

Settore automobilistico, aerospaziale, produzione di gioielli, energia rinnovabile, industria ferroviaria, industria energetica e altro.

Feedback dei clienti

Imballaggio

Supporto tecnico

Servizio di prevendita:

1. Consigliare macchine adatte in base alle esigenze del cliente

2. Supporto per richieste e consulenza

3. Supporto per il test dei campioni

4. Organizzazione di visite in fabbrica

Servizio in vendita:

1. Produzione secondo gli standard tecnici

2. Esecuzione di test di funzionamento delle apparecchiature

3. Controlli di qualità rigorosi prima della consegna

4. Consegna puntuale

Servizio post-vendita:

1. Garanzia di 18 mesi dalla data di consegna (12 mesi dal ricevimento)

2. Sostituzione gratuita per guasti non artificiali

3. Manutenzione in loco per problemi importanti dopo la garanzia

4. Ricambi a prezzo di costo a vita

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!