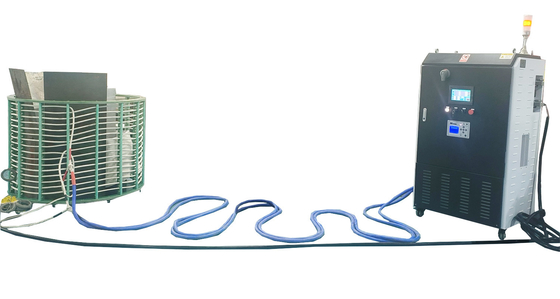

Manfuacturer sales Air cool;ed induction heating machine for Pre-heaitng pipeline welding:

Air cooled induction heating machine :

key advantage of Air cooled induction heating machine :

- Energy Efficiency:

IGBTs minimize switching losses, achieving >90% energy efficiency compared to traditional methods like gas furnaces .

- Compact Design:

Air-cooled systems eliminate bulky liquid cooling infrastructure, reducing machine size and weight .

- Precision Control:

Adjustable frequency (e.g., 20–100 kHz) and power levels enable uniform heating for applications like hardening, brazing, and annealing .

- Environmental Friendliness:

No harmful emissions, aligning with green manufacturing practices

Applications of Air cooled induction heating machine :

1. Automotive Manufacturing

Welding Preheating & Post-Weld Heat Treatment (PWHT):Preheats large pipelines (e.g., oil/gas pipelines) to reduce thermal stress during welding.Eliminates residual stress in automotive chassis components (e.g., brake discs, gear shafts) to enhance durability.

Surface Hardening:Hardens critical automotive parts (e.g., engine crankshafts, axle shafts) via induction hardening, improving wear resistance while maintaining toughness.

Battery Manufacturing:Used in thermal management systems for EV battery packs, ensuring uniform temperature distribution during assembly

2. Aerospace Industry

Aircraft Component Heat Treatment:Treats turbine blades, landing gear, and titanium alloys to meet stringent safety standards under extreme conditions.

Coating Removal:Safely removes industrial coatings from steel surfaces using induction dis bonding, minimizing material waste .

Radiator Cooling Systems:Optimizes heat dissipation in electric aircraft controllers by designing lightweight, air-cooled radiators

3. Metal Processing

Forging & Melting:Rapidly melts and forges metals (e.g., aluminum, steel) without traditional flame-based methods, ensuring uniform thermal distribution .

Annealing & Tempering:Softens hardened metals (e.g., stainless steel sheets) or adjusts hardness via controlled temperature cycles.

Brazing & Soldering:Joins dissimilar metals (e.g., copper to steel) using filler materials with low melting points, preserving base material integrity.

4. Electronics & Precision Engineering

Miniaturized Component Soldering:Assembles circuit boards and microelectronic devices with precision heating, avoiding thermal damage to sensitive parts .

Semiconductor Manufacturing:Supports wafer processing by heating silicon wafers for doping or annealing steps.

5. Renewable Energy Systems

Wind Turbine Production:at-treats gearbox components to withstand high mechanical loads in offshore wind farms .

Solar Panel Fabrication:Anneals photovoltaic cells to improve electrical conductivity and reduce defects

6. Industrial Maintenance & Repair

Equipment Stress Relief:Reduces residual stress in welded joints of heavy machinery (e.g., cranes, pipelines) to prevent fractures .

Tool & Die Maintenance:Restores hardness to worn-out molds or cutting tools via induction hardening, extending service life.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!